- Health & Beauty Protective Items Health & Medical Beauty & Personal Care

- Bags, Shoes & Accessories Luggage, Bags & Cases Shoes & Accessories

- Apparel, Textiles & Accessories Apparel Textile & Leather Product Fashion Accessories Timepieces, Jewelry, Eyewear

- Electronics Industrial Computer & Accessories Home Appliance Consumer Electronic Security & Protection

- Electronic Equipment, Component & Telecoms Electronic Equipment & Supplies Telecommunication

- Home, Lights & Construction Construction & Real Estate Home & Garden Lights & Lighting Furniture

- Gifts, Sports & Toys Gifts & Crafts Toys & Hobbies Sports & Entertainment

- Agriculture & Food Agriculture Food & Beverage

- Auto & Transportation Automobiles & Motorcycles Transportation

- Machinery, Industrial Parts & Tools Machinery Industrial Parts & Fabrication Services Tools Hardware Measurement & Analysis Instruments

- Metallurgy, Chemicals, Rubber & Plastics Minerals & Metallurgy Chemicals Rubber & Plastics Energy Environment

- Packaging, Advertising & Office Packaging & Printing Office & School Supplies Service Equipment

- K-Service Innotech Contents ICT Technology/Engineering

- ETC ETC

ITEM SPECIFICS

-

Brand

Model Degassing Flux for Melting Recycled/Secondary AlumDegassing Flux for Melting Recycled/Secondary Aluminum

-

origin

Republic of Korea

-

Size(Capacity)

KGS

-

Features

Reducing hydrogen content in the melt prior to casting

-

Material

NaCl, KCl, KAlF, etc.

PRODUCT DESCRIPTION

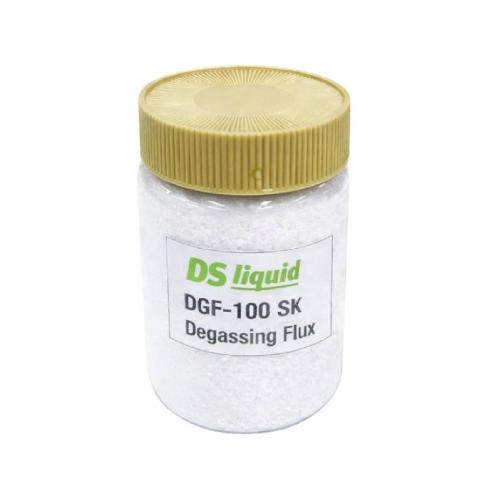

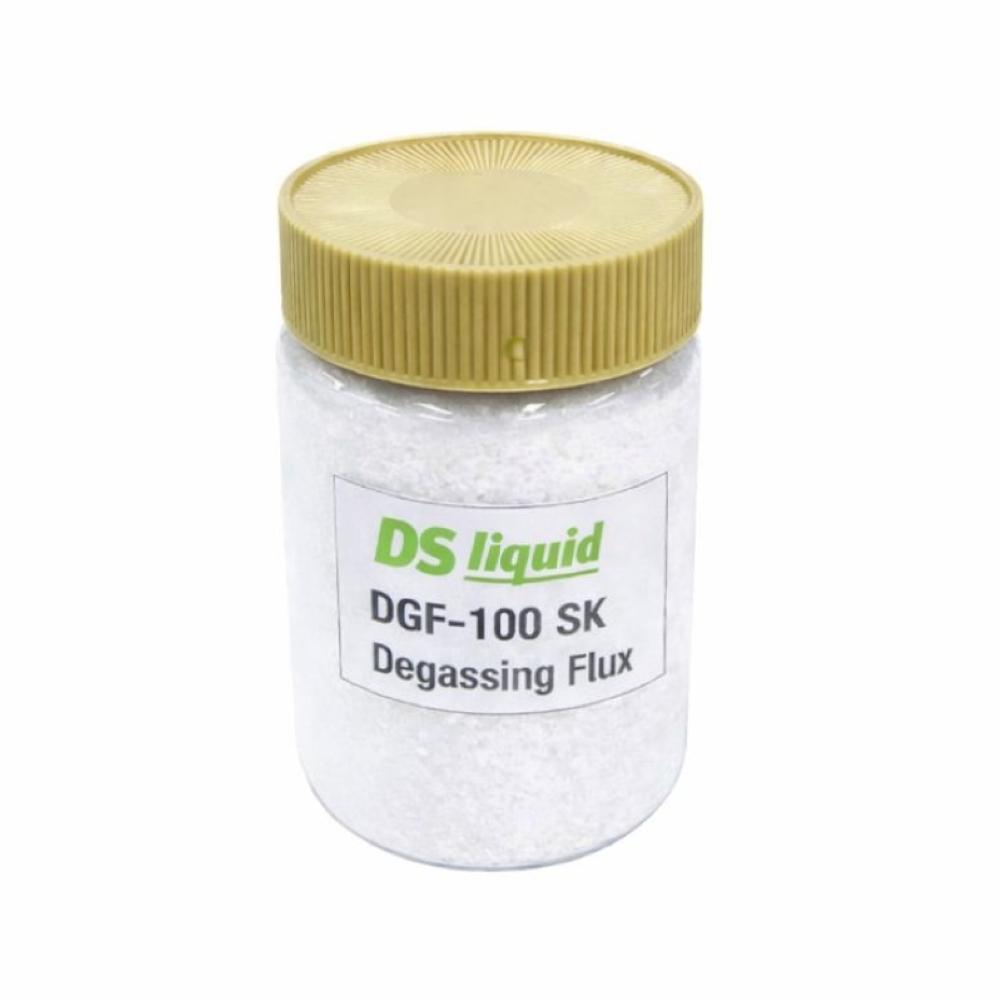

DS Liquid’s aluminum flux is a metallurgical auxiliary material (additives) designed for the melting and refining of recycled aluminum and secondary aluminum.

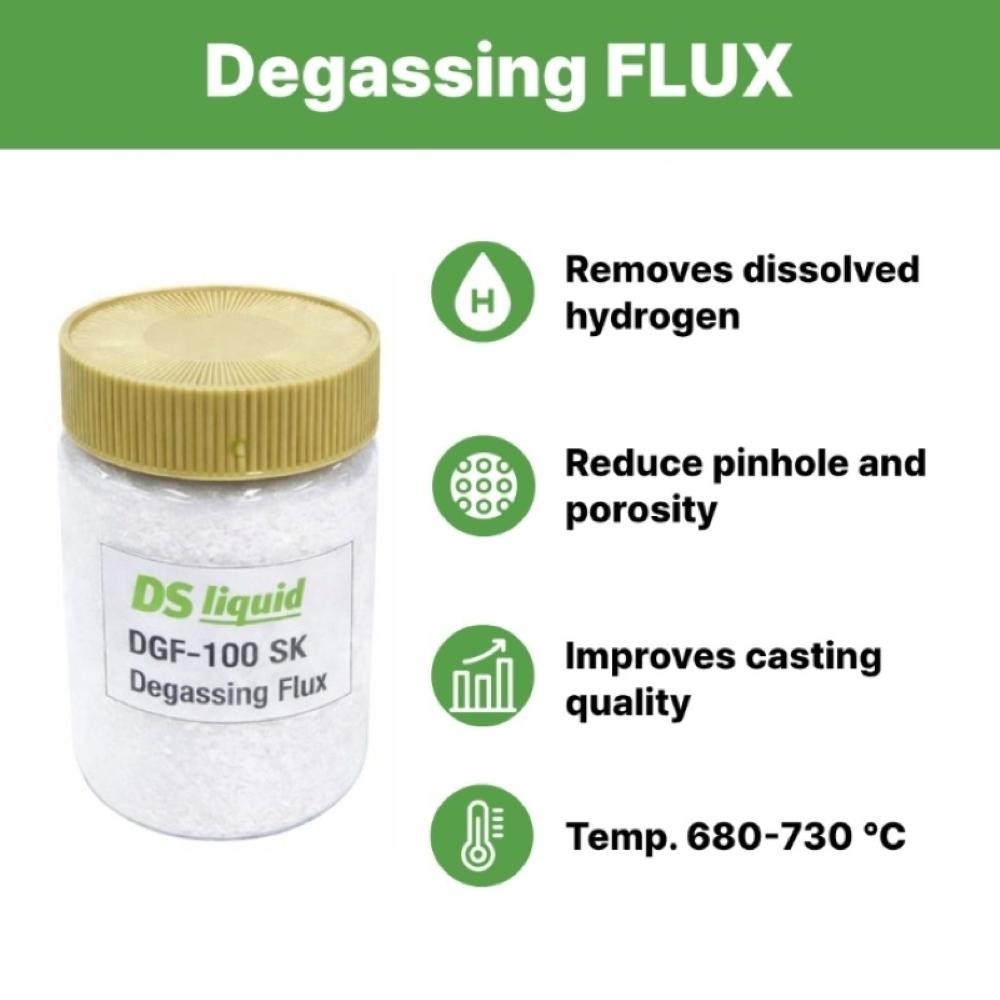

Degassing Flux (H₂ Gas Remover) is used to remove dissolved hydrogen gas from molten aluminum and other non-ferrous metals, helping to prevent pinhole defects and porosity formation in the final cast product.

DS Liquid’s Degassing Flux (H₂ Gas Remover) is a product range developed to effectively address hydrogen-related defects in secondary (recycled) aluminum and non-ferrous metal melting processes.

During melting and holding, molten aluminum readily absorbs hydrogen due to moisture, scrap contamination, and surrounding process conditions.

Excess hydrogen can lead to pinhole defects and internal porosity in cast products, negatively affecting quality and mechanical properties.

Degassing Flux is added to the molten metal to react with and release dissolved hydrogen, thereby reducing hydrogen content in the melt prior to casting.

This results in fewer internal defects, improved surface quality, and more stable mechanical performance of the final product.

The product range includes Na-based and Non-Na-based formulations, available in powder and tablet forms, allowing flexible selection depending on process requirements.

Recommended operating temperatures typically range from 680°C to 730°C or above, depending on the specific grade.

Degassing Flux is suitable for a wide range of aluminum processes including die casting, rolling, and extrusion, particularly at the melt treatment stage before casting.

Technical data sheets (TDS) and test reports are available upon request.

Customized application conditions can be discussed based on furnace type, melt temperature, and feed material characteristics.

For more detailed information on our products and manufacturing processes, please visit our website

(https://www.dsliquid.com/en/products/fifth)

|

Item |

Description |

|

Product Type |

Degassing Flux (Hydrogen Gas Remover) |

|

Process Application |

Aluminum melting and refining processes, pre-casting melt treatment |

|

Key Functions |

Removal of dissolved hydrogen / Reduction of pinholes and porosity |

|

Expected Benefits |

Improved casting quality, reduced internal defects, higher product reliability and yield |

|

Support |

Process-based customization (furnace type, temperature, feed condition), QC and |

1. Flux for General Purpose

| Category | Purpose of Use | Product Name | Na | Form | Temp(℃) |

| H₂ gas remover |

▪This product removes H₂ gas in molten metals. ▪This product can prevent pin holes/porosities from forming in the final product. |

DGF-200YG | Na-based | Powder | 700 or above |

| DGF-200H | 700 or above | ||||

| DGF-500N | 700 or above |

2. Non-toxic Flux for General Purposes

| Category | Purpose of Use | Product Name | Na | Form | Temp(℃) |

| H₂ gas remover | ▪This product removes H₂ gas in molten metals. ▪Prevents pinholes and porosity formation. |

A-100NF | Non-Na-based | Powder | 710 or above |

| A-100SK(#2) | Na-based | Powder | 710 or above | ||

| DGF-100SK | Na-based | Powder | 680 or above | ||

| DGF-200YG | Na-based | Powder | 710 or above | ||

| DGF-300LM | Na-based | Powder | 710 or above | ||

| DGF-400PJ | |||||

| ENF-50N-2 | Na-based | Powder | 710 or above | ||

| AS-10 | Na-based | Tablet | 710 or above | ||

| D-109 | Na-based | Tablet | 680~730 |

PAYMENTS DETAILS

- Letter of Credit : L/C(sight)

- Document against Payment : D/P

- Document against Acceptance : D/A

- Cash Against Document : CAD

- Telegraphic Transfer : T/T

- Name : David Park

SHIPPING

- 705 Haean-ro Sangnok-gu, Ansan-si, Gyeonggi-do (15588)

The person in charge

Joongyong SongAddress

705 Haean-ro Sangnok-gu, Ansan-si, Gyeonggi-do (15588)

DS Liquid

-

- Business Type :

- Manufacturer

-

- Main Product :

- Molten Aluminum, Aluminum Recycled Scarp Ingot, Flux, Aluminum Granule, etc.

-

- Established :

- 1986-09-09

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 51~100 people

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 6,000,000

-

- Number of foreign trade employees

- 51~100 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- DS Liquid Co.,Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

How to

Use

How to

Use